Leaks can lead to significant problems in various industries. Whether it’s in manufacturing, medical equipment, or aerospace, ensuring the integrity of systems is crucial. One of the most reliable ways to detect leaks is by using a helium leak detector. This device has gained prominence because of its accuracy, efficiency, and versatility. In this article, we will explore how a helium leak detector works, its benefits, applications, and why it is particularly essential for the Indian market.

What Is a Helium Leak Detector?

A helium leak detector is a device designed to identify and locate leaks in systems by detecting helium gas. Helium is used because it is inert, safe, and has small, lightweight molecules. These characteristics allow helium to penetrate tiny leaks easily, making it an ideal tracer gas for leak detection. A helium leak detector can identify even the smallest leaks, ensuring that the system is airtight and functioning optimally.

How Does a Helium Leak Detector Work?

The principle behind a helium leak detector is straightforward. The system under test is filled or pressurized with helium gas. If there is a leak, the helium will escape and be detected by the helium leak detector. The detector then measures the concentration of helium and pinpoints the location of the leak. There are two main methods of testing:

- Vacuum Testing: The system is evacuated, and the helium is sprayed around it. If there is a leak, helium enters and is detected by the device.

- Pressurization Testing: The system is pressurized with helium, and the detector scans the exterior for escaping gas.

Both methods are effective and are used depending on the type of system being tested.

Benefits of Using a Helium Leak Detector

A helium leak detector offers several advantages that make it the preferred choice for leak detection:

High Sensitivity

Helium leak detectors can detect extremely small leaks, often in the range of 10^-12 mbar∙L/s. This level of sensitivity ensures that even the tiniest leaks are found, which might be undetectable with other methods.

Fast and Accurate

These detectors provide immediate results, allowing technicians to quickly identify and address any issues. The accuracy of the helium leak detector also means fewer false positives, saving time and resources.

Versatile and Safe

Helium is a non-toxic, non-flammable gas, making it safe for use in a variety of settings. This versatility allows helium leak detectors to be used across many industries without concerns about hazardous reactions or environments.

Cost-Effective

While the initial investment in a helium leak detector can be high, it pays off in the long run. By identifying leaks early, companies can avoid costly repairs, product recalls, or system failures. Over time, the cost savings outweigh the initial expense.

Applications of Helium Leak Detectors

Helium leak detectors have a wide range of applications across different industries:

Automotive Industry

In the automotive sector, ensuring that components such as fuel systems, air conditioning units, and engines are leak-free is essential for safety and performance.

Medical Equipment

Medical devices, such as MRI machines and oxygen tanks, require leak-free systems to operate safely. A helium leak detector helps in ensuring that these devices meet strict safety standards. This is particularly important in the medical field where even minor leaks can have serious consequences.

Why the Indian Market Needs Helium Leak Detectors

India’s industrial sector is growing rapidly. As the country expands its manufacturing capabilities, there is an increasing demand for reliable, high-quality testing equipment. The helium leak detector plays a crucial role in ensuring product quality and safety across various sectors. Here are some reasons why this technology is essential in the Indian market:

Growing Manufacturing Industry

India is becoming a global hub for manufacturing, particularly in sectors like automotive, electronics, and medical devices. For these industries, maintaining quality control is critical. A helium leak detector ensures that products meet international standards, which is vital for export.

Increased Focus on Safety

Safety regulations in India are becoming stricter. Industries are required to adhere to safety standards, and leak detection is a part of this compliance.It allows companies to ensure that their systems and products are safe for use, reducing the risk of accidents and liability.

Cost Savings in the Long Run

In a competitive market, cost efficiency is key. Although the initial cost of a these detector can be high, the long-term benefits make it a worthwhile investment. By detecting leaks early, companies can save on repair costs, minimize downtime, and avoid product recalls.

Types of Helium Leak Detectors

There are different types of helium leak detectors available, each designed for specific applications.

Portable Helium Leak Detectors

These are lightweight and easy to transport, making them ideal for fieldwork.

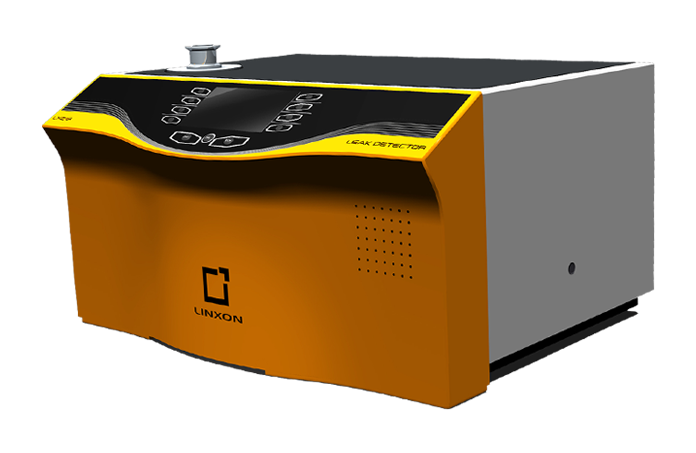

Stationary Helium Leak Detectors

These units are designed for use in production lines. They can handle large volumes and are suitable for continuous testing in a factory setting.

Mass Spectrometer Helium Leak Detectors

These are high-precision detectors that use a mass spectrometer to identify helium atoms. They are ideal for applications that require extremely high sensitivity and accuracy.

Choosing the Right Helium Leak Detector

Selecting the right helium leak detector depends on several factors. Here are some considerations to keep in mind:

Sensitivity Requirements

Depending on the application, the required sensitivity may vary. For example, in the aerospace industry, extremely high sensitivity is necessary, while less precision might be acceptable in other sectors.

Mobility Needs

Consider whether a portable or stationary unit would better suit your needs. If you need to move the detector between locations, a portable helium leak detector is ideal.

Budget Constraints

While high-end detectors offer more features, they come with a higher price tag. Assess your budget and choose a device that offers the best balance between cost and functionality.

Maintenance and Calibration of Helium Leak Detectors

To ensure the accuracy and reliability of a helium leak detector, regular maintenance and calibration are essential. Calibration ensures that the device remains sensitive and precise over time. Regular maintenance checks help in identifying wear and tear, ensuring that the detector remains in optimal working condition. This is particularly important for industries that rely on continuous, accurate leak detection.

Conclusion

This is a critical tool for industries that require airtight systems. Its ability to detect even the smallest leaks makes it indispensable for applications where safety, quality, and performance are paramount. For the Indian market, this technology is becoming increasingly important as the country’s manufacturing sector grows and safety regulations become stricter. Investing in this can lead to significant cost savings, enhanced product quality, and compliance with safety standards. Whether for automotive, medical, aerospace, or refrigeration, this is an investment that pays off in the long run.

By understanding how it works, its benefits, and its applications, businesses can make informed decisions about integrating this essential tool into their quality control processes.